Sludge treatment − an overview of aerobic digestion

How aerobic digestion works

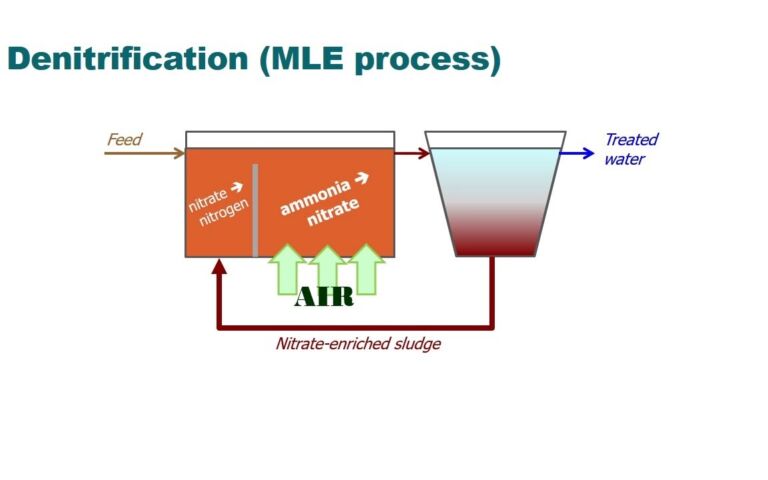

Aerobic digestion is the degradation of the organic sludge solids in the presence of oxygen. The oxygen is introduced as fine bubbles of air into the reactor. The micro-organisms in the sludge convert the organic material to carbon dioxide and water, and the ammonia and amino species to nitrate.

Aerobic digestion resembles the conventional activated sludge (CAS) process (see video below) but excludes a wastewater feed and employs longer solids retention times. However, since in aerobic digestion there is no feedwater entering the system − and therefore no new supply of organic substrate to sustain the micro-organisms − they begin to die and are used as food by other bacteria. This stage of the process is known as endogenous respiration and is responsible for reducing the sludge organic solids concentration.

Conventional activated sludge (CAS) process

Aerobic digestion is generally lower in capital cost than anaerobic digestion (AD) for plants below 20,000 m3/d wastewater capacity. In addition, aerobic digestion:

- is simple in construction, requiring no tank covering

- more easily operated and controlled than AD

- does not generate nuisance odours

- can process sludges with a high nutrient content

- generates supernatant streams having low in BOD and nutrient concentrations

- removes ammoniacal compounds, and

- achieves a similar VSS removal (40−50%) as that for AD.

As with AD, the process produces a relatively stable sludge end product and reduces the pathogenic content.

The primary disadvantage with aerobic digestion is that it is energy intensive: the process consumes air and generates carbon dioxide rather than methane as the main gaseous end product. Also, the digested sludge is not as readily dewaterable mechanically.

As with AD, aerobic digestion can be designed as a single or multi-tank process, with the multi-tank process providing greater process efficiency by reducing the required solids residence time. Also, as with AD, the process can be operated under mesophilic (i.e. ambient temperatures) and thermophilic (elevated temperatures, normally 55−70°C) conditions.

Thermophilic conditions provide more rapid biochemical reactions, reducing the reactor retention times and so the tank sizes, and forms the basis of Autothermal Thermophilic Aerobic Digestion (ATAD). Because the biochemical aerobic degradations reactions under thermophilic conditions are exothermic, the ATAD process can be sustained with no external heat source required provided:

- the feed sludge is thickened to a solids concentration of 2.5−5% volatile solids concentration, and

- the tank is sufficiently well insulated to reduce heat losses as much as possible.

However, at the high operational temperatures employed, some of the disadvantages of classical aerobic digestion are lost. Specifically, for ATAD:

- no nitrifiers exist for biodegrading any amino or ammoniacal species that might be in the feed sludge, contributing to the odour issue associated with the process, and

- the solubility of oxygen is reduced, such that either greater energy is needed to aerate the digesting sludge with air or a high-purity oxygen source is needed to sustain the process biochemistry.

Standard aerobic digestion can also be combined with the CAS process to reduce sludge waste volumes, and forms the basis of the extended aeration process. In extended aeration, the solids retention time is normally 20−40 days, compared with 5−15 days for the CAS process, to allow further degradation of organic and biological content of the reactor solids. The use of aerobic degradation of organic solids also forms the basis of composting.

How sludge composting works

Composting is a type of aerobic digestion. Sewage sludge can be combined with other waste materials such as wood chip, straw or green wastes prior to composting to provide a pasteurised product. Around 20−30% of the volatile solids can be converted to carbon dioxide through composting.

Composting employs natural mesophilic and thermophilic aerobic degradation within a largely static system which is aerated by natural diffusion and is therefore low in energy demand. However, composting is a lengthy process and employs large land areas.

The most established method for composting is through the use of windrows. These are simple piles of material, ~2m deep and ~4m wide, which are periodically mechanically turned to ensure even distribution of the organic materials and adequate contact with air. The process temperature must be kept between 55 and 65°C and the moisture content at 35−65% for degradation to take place at a reasonable rate and for the pathogenic microorganisms to be destroyed. The process takes around six months.

The materials for combining with sludge prior to composting are categorised as either bulking agents or amendments, where:

- a bulking agent (wood chips, shredded leaves or tyres) is intended to support the structure of the sludge by increasing its porosity to encourage effective aeration, and

- an amendment (e.g. sawdust, straw, rice hulls, recycled compost) is primarily used to increase the organic content and enhance biodegradability.

Both these agents are added to the sludge at the start of the composting process, which proceeds via the following stages:

- preprocessing, where the sludge is mixed with the bulking agent(s) and amendments

- high-rate decomposition, with aeration by air pumping or mechanical turning

- recovery of the bulking agent (if largely undegraded)

- curing and storage to provide stabilisation, and

- post processing, consisting of (i) screening to remove unbiodegradable materials such metals and plastics, and/or (ii) grinding/comminution to produce a more uniform product.

The product may then be used for soil conditioning or other land applications, provided the metals content is sufficiently low.