Aeration costs in MBRs

Membrane and process aeration

Energy demand is a key cost factor in MBR technology. The main contributors to energy costs are sludge transfer, permeate production and, most significantly, aeration.

Membrane aeration is normally achieved via coarse bubble aerators positioned beneath the membrane units.

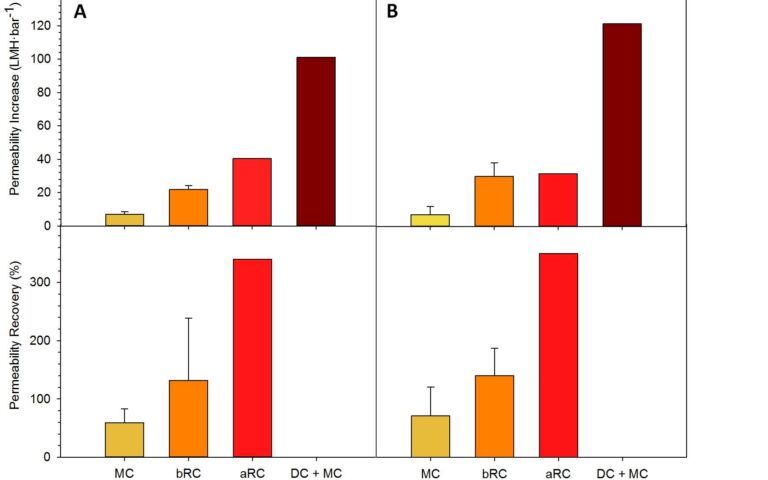

Aeration demanded for membrane scouring can be normalised to produce the specific aeration demand (SAD). Normalisation can be either against the membrane area (SADm, taking units of Nm3/(m2.h)) or against the permeate volume (SADp, Nm3/m3).

SADp is then directly proportional to the specific energy demanded for membrane air scouring, or SEDAm, since all other components of air pumping (namely the blower efficiency, aerator depth, inlet air pressure, aerator type, and ratio of air to water enthalpy) are constant for a specific installation. Since SADp is the ratio of SADm to the flux in consistent units, i.e. in m/h, energy efficiency is improved both by increasing the sustainable flux and decreasing the membrane air scour rate required to sustain this flux.

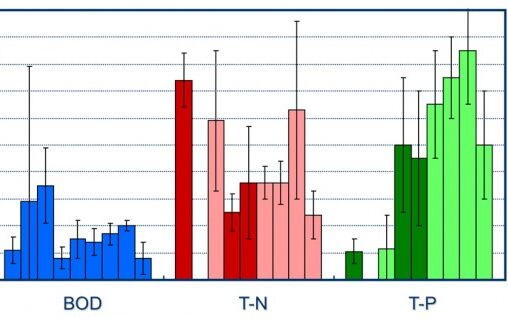

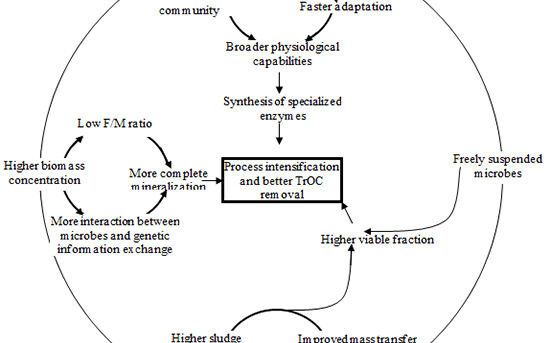

Aeration demanded for biological treatment, often referred to as the ‘process aeration’, is dependent primarily on the inlet and outlet biodegradable organic carbon and 'Kjeldahl' nitrogen levels, Kjeldahl nitrogen (KN) being biologically oxidisable nitrogen. The absolute difference between inlet and outlet defines the load, which then determines the oxygen demanded to convert the organic carbon to carbon dioxide and KN to nitrate ('nitrification').

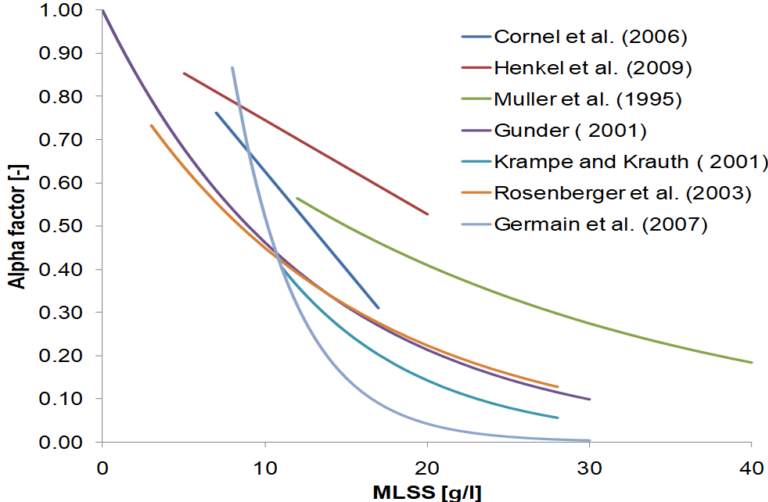

The actual aeration rate demanded to deliver a specific dissolved oxygen (DO) concentration is dependent on key design parameters, such as the aerator type and the depth to which it is submerged in the tank, the residual DO and sludge solids concentration. The efficiency of transfer of oxygen from air into the sludge is defined by the 'alpha factor' (α), which is simply the ratio of the mass transfer coefficient of water to that of the sludge. α decreases with solids concentration according to trends which appear to vary widely between different studies (Fig. 1) but which generally follow a pseudo-exponential relationship.

So, according some of the relationships shown in Figure 1, the aeration rate required to maintain a specified DO residual may double between a process sludge solids concentration of 7 and 12 g/L. However, the nature of the alpha factor:MLSS relationship is complicated and influenced by parameters such as the mixed liquor microbiology and and surfactant levels.