About sludge stabilisation

Sludge stabilisation overview

Stabilisation processes as applied to sludge are those which reduce its:

- odour and putrescence (i.e. decay), and

- level of pathogenic organisms.

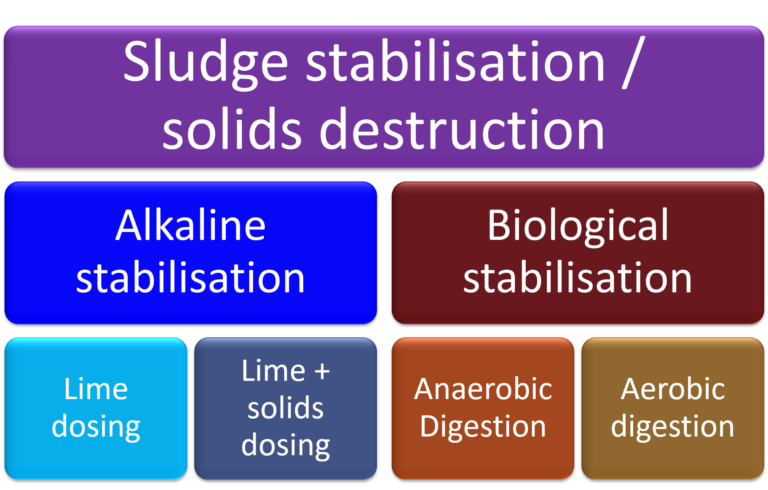

This is generally achieved either chemically or biologically.

For alkaline stabilisation, a basic chemical reagent such as lime − sometimes supplemented with a granular or powdered solid − is dosed into the sludge. Biological stabilisation employs micro-organisms which develop naturally within the sludge under the reactor conditions employed to biochemically degrade the organic material. This can be conducted under aerobic (in the presence of oxygen) or anaerobic (absence of oxygen) conditions.

Sludge can also be stabilised by applying intense heat, either in the presence or absence of oxygen. These processes are normally referred to as thermochemical. They demand a substantially different system design approach.